The process of mattress manufacturing in India has long been a mystery to many consumers.

In this blog post, we will take a closer look at the process of mattress manufacturing in India, from start to finish.

From the sourcing of materials to the final product, we will explore all aspects of mattress manufacturing in India. By the end of this post, you will have a better understanding of how your mattress is made and what goes into the process.

Topics covered in this article

ToggleThe Indian mattress market overview

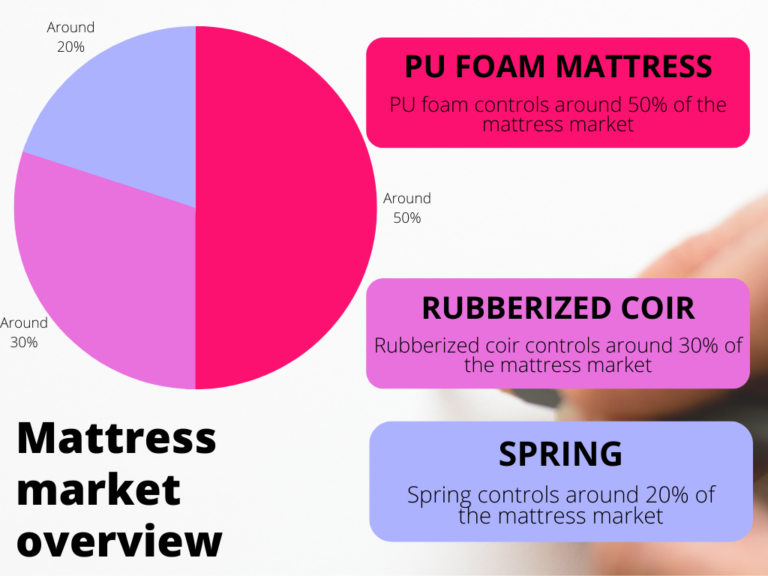

The mattress industry in India has valued at INR 10,000 Crores and comprises Rubberized Coir, PU Foam, Spring, and Latex Foam.

It has been growing by 8-10% per year (for the last 5 years) with 70% unorganized and 30% organized industry. Among the organized market, PU foam controls around 50% of the market; coir contributes around 30%, and spring mattresses for 20%.

Historically, rubberized coir mattresses used to represent 50% of the Indian mattress market but in recent decades PU foam has had a great demand.

Overall Design for mattress manufacturing

Mattress manufacturers produce their products according to standard sizes. These sizes were implemented in order to prevent any discrepancies from happening between companies that manufacture beds and mattresses.

The bed sizes include the twin bed, 39 inches wide and 74 inches long; the double bed, 54 inches wide and 74 inches long; the queen bed, 60 inches wide and 80 inches long; and the king bed, 78 inches wide and 80 inches long.

The “core” of a typical mattress is the innerspring unit, which is a series of wire coils that join together.

The upholstery layers are attached to the innerspring: the first, called the insulator, sits directly on top of the coil and prevents the next layer, which is the cushioning, from molding to it. While these cushioning layers vary, there are two different types: open-cell foam and fiberfill.

Some mattresses can also have up to eight cushioning layers that range from 1/4 inch to 2 inches (.63 to 5 centimeters) in thickness.

A Variety of springs are used in mattress manufacturing

Springs come in many varieties and each one is designed for a specific purpose.

The most common coil, the Bonnell spring, is hourglass-shaped and knotted at both ends.

The Offset spring design is also hourglass-shaped with flattened areas that allow it to move back and forth more easily than the Bonnell.

Continuous inner springs consist of one long piece of wire which has been bent into s-shaped units that are then enclosed in a fabric casing.

Lastly, in the Pocket spring System, each coil is individually cased where they can all be snapped together like pockets.

Mattresses consist of hundreds of springs and coil wires which can be joined in several ways.

One common method is coiling, where the coils are connected by wires shaped like corkscrews running on the top and bottom of the springs to lace them together. Rigid border wires may be added around the circumference to stabilize the unit.

What are the most common materials used in mattresses today?

Mattresses used to be made of many materials, including both natural and synthetic options.

Today, the most common materials used in mattresses are polyurethane foam, latex foam, and innerspring coils.

Polyurethane foam is a synthetic material that is made from petroleum products.

Latex foam is made from rubber tree sap and is often considered to be more natural than polyurethane foam. Innerspring coils are metal springs that provide support and bounciness to a mattress.

The spring-type mattress is typically made from wire, the box spring wire is usually heavier than the type of wire that’s used in a spring-type mattress.

The inside insulator is most often made from semi-rigid netting or mesh and comfort layers are normally made with materials such as natural fiber, polyurethane foam, or polyester.

The flanges are often made of fabric and hog rings are typically made of metal. The top, bottom, and sides consist of a durable fabric that covers a polyester foam or fiber backing. The ticking that holds the fabric together is made of heavy-duty synthetic material.

The process of making a mattress in India

A mattress is a large, rectangular piece of soft furniture that is used for sleeping on.

It typically consists of two layers – a base layer and a top layer – that are separated by a layer of springs or foam. The base layer is usually made from wood or metal, while the top layer is usually made from padding, fabric, and other materials.

The manufacturing process of a mattress begins with the design and development stages. This is the primary stage of the mattress manufacturing process in India.

During this stage, manufacturers work to create a prototype of the mattress that meets all safety and quality standards. Once the prototype is approved, the manufacturer will move on to the production stage.

During the production stage, all of the materials needed to create the mattress will be sourced and gathered. The next step is to assemble the mattress, which includes putting all of the layers together and attaching them securely.

Once the mattress is assembled, it will undergo a series of tests to ensure that it meets all quality standards. Finally, the mattress will be packaged and shipped to retailers or consumers.

The problem with shipping a mattress is that it takes up so much space. You can tackle this by compressing it, and then there’s also a way to ship it as well.

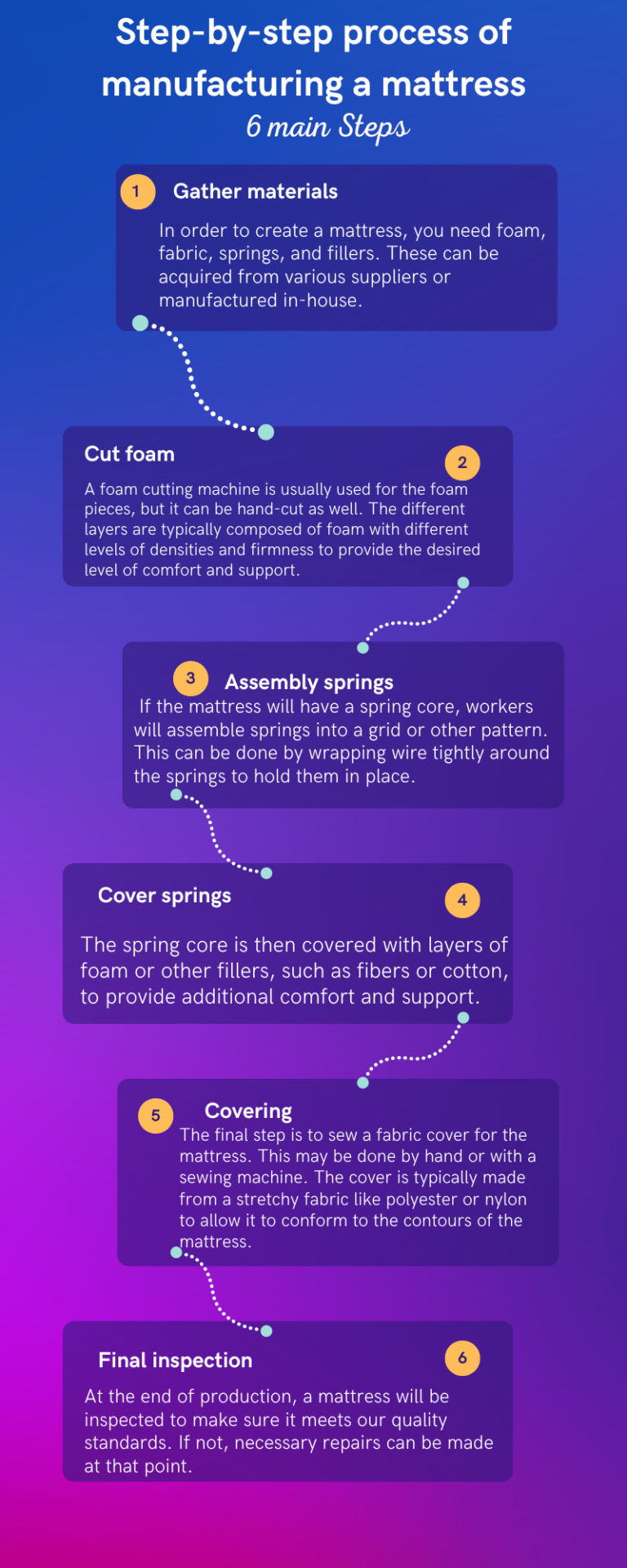

Step-by-step process of manufacturing a mattress:

1. Gather materials: In order to create a mattress, you need foam, fabric, springs, and fillers. These can be acquired from various suppliers or manufactured in-house.

2. Cut foam: A foam cutting machine is usually used for the foam pieces, but it can be hand-cut as well. The different layers are typically composed of foam with different levels of densities and firmness to provide the desired level of comfort and support.

3. Assembly springs: If the mattress will have a spring core, workers will assemble springs into a grid or other pattern. This can be done by wrapping wire tightly around the springs to hold them in place.

4. Cover springs: The spring core is then covered with layers of foam or other fillers, such as fibers or cotton, to provide additional comfort and support.

5. Covering: The final step is to sew a fabric cover for the mattress. This may be done by hand or with a sewing machine. The cover is typically made from a stretchy fabric like polyester or nylon to allow it to conform to the contours of the mattress.

6. Final inspection: At the end of production, a mattress will be inspected to make sure it meets our quality standards. If not, necessary repairs can be made at that point.

7. Packaging and Shipping: After the finished mattress is made, it’s packaged and shipped to a partner retailer or directly to the customer’s doorstep.

These are the main mattress manufacturing process in India.

How the different parts come together

The different parts of a mattress come together through a process of layering and stitching. The first layer is the fabric, followed by the padding and then the coils. The coils are stitched together with the fabric to create the finished product.

What are the parts of a mattress and what do they do?

A mattress is made up of several different parts, each with its own specific function. The most important part of a mattress is the springs, which provide support and comfort. The springs are usually made of steel, and they are what give a mattress its firmness.

The next layer is the padding, which provides cushioning and helps to distribute weight evenly. There are many different types of padding, including foam, down, and fiberfill.

The outer layer of a mattress is called the ticking. This is what gives the mattress its shape and protects the inner layers from wear and tear. Ticking can be made from a variety of materials, including cotton, polyester, and nylon.

Then there are the side panels, which provide structure and support to the sides of the mattress. They also help to keep the springs in place.

Finally, there is the foundation, which provides a flat surface for the mattress to rest on. It also helps to absorb impact and keep the springs from sagging over time.

How is the structure of a mattress created?

A mattress is made up of several different layers, each with a specific purpose. The most important layer is the support layer, which provides the foundation for the rest of the mattress. The support layer is usually made up of coils or springs, which are designed to evenly distribute weight and provide support for the sleeper.

Above the support layer is the comfort layer, which is designed to provide cushioning and contouring for the sleeper. The comfort layer is often made up of foam, latex, or other materials that offer a soft feel.

Finally, the topmost layer of a mattress is the cover, which serves to protect the inner layers from dirt and debris. The cover is typically made from fabric such as cotton or polyester.

How long does it take to produce a single mattress?

It takes approximately one day to produce a single mattress. The process begins with the fabrication of the steel coils, which are then heat-treated and tempered to create a springy foundation.

Next, layers of cotton batting and/or foam are added for comfort, followed by a layer of fabric.

The final step is to add the quilted top, which is usually made from polyester.

The different types of mattresses made in India

The different types of mattresses made in India include coil springs, orthopedic, latex, and foam. Each type of mattress has its own unique benefits that can help you get a good night’s sleep.

Coil spring mattresses are one of the most popular types of mattresses in India.

They are made with coils that provide support and comfort for your body. Orthopedic mattresses are designed to provide support for your back and spine. They are a good choice for people who have back pain or other medical conditions that require extra support.

latex Mattresses are made with natural latex that is sourced from rubber trees. They are known for being durable and providing excellent support for your body.

Foam mattresses are made with different types of foam, including memory foam. They are designed to contour your body and provide support where you need it most.

The benefits of sleeping on a good supportive mattress

A good mattress is one of the most important investments you can make for your health. It’s not just about comfort — a supportive, well-made mattress can help relieve back pain, improve your sleep quality, and reduce stress levels.

There are a few things to keep in mind when shopping for a new mattress, such as firmness, size, and budget.

Here are a few benefits of sleeping on a good supportive mattress:

- Relief from back pain: A good mattress provides support for your spine and helps to keep your body in alignment while you sleep. This can help to alleviate back pain and prevent pressure points from forming.

- Improved sleep quality: A supportive mattress helps you to get a deeper, more restful sleep by reducing tossing and turning. This leads to improved sleep quality and overall better health.

- Reduced stress levels: When you wake up feeling well-rested and without aches or pains, you’re less likely to feel stressed throughout the day. This can lead to improved mental clarity and focus, as well as increased energy levels.

Conclusion

The mattress manufacturing process in India is quite fascinating. From the collection of raw materials to the final product, it is clear that a lot of effort and expertise goes into making a quality mattress.

If you are in the market for a new mattress, we hope that this article has given you a better understanding of what goes into making one and how to choose the right one for you.

If you find this article about the mattress manufacturing process in India helpful, don’t forget to share it and comment with your thoughts.

Thank you for reading!

Be the first to comment